PHOTO GEAR RESTORATION BOSCH 33A13/14 ⇐ Bosch

-

alexbak2020

PHOTO GEAR RESTORATION BOSCH 33A13/14

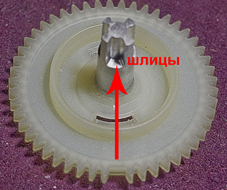

The splines of the gear that rotates the water flow switch disks have broken. Restoration was carried out. But it seems to me that the splines were positioned incorrectly in relation to the key. Tell me how to do it correctly, or just a photo of this gear.

-

- PHOTO GEAR RESTORATION BOSCH 33A13 14 - shlic.jpg (56.22 KiB) Viewed 92436 times

-

- PHOTO GEAR RESTORATION BOSCH 33A13 14 - shest.jpg (70.78 KiB) Viewed 92436 times

-

Oleg

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

Hello,

I recently encountered the same problem. The splines on the same gear are worn out.

Tell me how you restored them (namely, how you secured the metal axis to the gear itself).

And the second question, the gear fits the key with the previous gear, but the throttle valve itself can be put on the gear splines in four different positions. How to correctly match the valve with the key on the gear?

Thank you.

bil_oleg@mail.ru

I recently encountered the same problem. The splines on the same gear are worn out.

Tell me how you restored them (namely, how you secured the metal axis to the gear itself).

And the second question, the gear fits the key with the previous gear, but the throttle valve itself can be put on the gear splines in four different positions. How to correctly match the valve with the key on the gear?

Thank you.

bil_oleg@mail.ru

-

Sasha

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

Good afternoon. The splines on the gear axis are not the same. Three are narrow, one is wide and it is located on the opposite side of the missing tooth on the outer circumference of the large gear.

Good luck!!!

Good luck!!!

-

Gennady

- Total posts: 1

- Joined: 10.05.2017

- My dishwasher: Bosch Silence Plus

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

Comrades, help out!

During the partial disassembly of the bottom of the PMM, the actuator motor (water flow distributor) was removed and then put back. But the problem is that the plate (damper) in which there are several holes was shifted by me relative to its original position and now, when starting the washing program, there are 3 - 4 attempts by the pump to pump water through the holes of this plate, but because... it is not in the required position, error code E-21 is issued. The question is, how to find the correct (zero or starting) position of this plate?

During the partial disassembly of the bottom of the PMM, the actuator motor (water flow distributor) was removed and then put back. But the problem is that the plate (damper) in which there are several holes was shifted by me relative to its original position and now, when starting the washing program, there are 3 - 4 attempts by the pump to pump water through the holes of this plate, but because... it is not in the required position, error code E-21 is issued. The question is, how to find the correct (zero or starting) position of this plate?

-

Semyon 74

-

Farsan

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

Good afternoon!

I have the same problem with BOSCH 33A13/14

Background...

Failures: 1) Malfunction of the E-24 circulator pump

2) Water leakage E-14 in the wash.

How I fixed everything:

1) Replaced the bushings

2) Put the machine into operation in different modes, no leaks could be detected. I decided to check the condition of all gaskets, seals, and seal them at the same time.

2*) What is my mistake and essentially the problem that I cannot fix. I disassembled the flow regulator or actualizer, which is located on the water path from the circus pump to the sprinklers. When I started assembling I discovered that there was no actualizer position sensor; accordingly, there is some kind of zero position relative to which the machine starts working. Let me remind you that the actualizer consists of: a damper with holes, two gears (driven, driving), a motor (main actuator). In search of a solution to the problem, I established how to match the teeth so that the long tooth coincides with the “empty” tooth on the driven gear. But they don’t write anywhere about how to install the damper itself. I discovered through experience that the damper can be installed/removed in 4 different ways. I chose one of them, assembled and installed the damper. The machine completed the program without errors (the cyclic pump was working, you could hear it), but the sprinklers remained dry.

Does anyone know how to install the damper correctly? Who disassembled and remembers how the damper stood or held a new pump in their hands???

I have the same problem with BOSCH 33A13/14

Background...

Failures: 1) Malfunction of the E-24 circulator pump

2) Water leakage E-14 in the wash.

How I fixed everything:

1) Replaced the bushings

2) Put the machine into operation in different modes, no leaks could be detected. I decided to check the condition of all gaskets, seals, and seal them at the same time.

2*) What is my mistake and essentially the problem that I cannot fix. I disassembled the flow regulator or actualizer, which is located on the water path from the circus pump to the sprinklers. When I started assembling I discovered that there was no actualizer position sensor; accordingly, there is some kind of zero position relative to which the machine starts working. Let me remind you that the actualizer consists of: a damper with holes, two gears (driven, driving), a motor (main actuator). In search of a solution to the problem, I established how to match the teeth so that the long tooth coincides with the “empty” tooth on the driven gear. But they don’t write anywhere about how to install the damper itself. I discovered through experience that the damper can be installed/removed in 4 different ways. I chose one of them, assembled and installed the damper. The machine completed the program without errors (the cyclic pump was working, you could hear it), but the sprinklers remained dry.

Does anyone know how to install the damper correctly? Who disassembled and remembers how the damper stood or held a new pump in their hands???

-

Anti_Tip

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

The central gear has 1 wide tooth; it fits into a wide groove in the other gear. And the reverse side is a plate with holes, there is only 1 docking option.

-

Common man

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

I encountered a similar problem. After disassembly and assembly, the lower sprinkler stopped working; when checking during operation, it turned out that the valve was half-closed (when removing the sprinkler in the fitting, it was clear that the supply was blocked by the plate).

As said above, everything is assembled in one version - a wide tooth on wide groove, the plate fits onto the gear crosspiece in only one version.

But also, after some thought, I set the gears as the initial position so that during the first revolution (along the direction of rotation), the wide tooth of the large gear is the first to make contact.

I started it, it seems to be working, I checked the damper during operation - it is open.

But a small problem appeared, now the dishwasher, at the beginning of the wash cycle, thinks for a long time between the stages - turning on-draining-water supply-washing. Does anyone have an opinion or experience with this?

As said above, everything is assembled in one version - a wide tooth on wide groove, the plate fits onto the gear crosspiece in only one version.

But also, after some thought, I set the gears as the initial position so that during the first revolution (along the direction of rotation), the wide tooth of the large gear is the first to make contact.

I started it, it seems to be working, I checked the damper during operation - it is open.

But a small problem appeared, now the dishwasher, at the beginning of the wash cycle, thinks for a long time between the stages - turning on-draining-water supply-washing. Does anyone have an opinion or experience with this?

-

Abyssinian Well

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

Good afternoon SPV53 (45cm). There was a similar problem: error E04 came on, it stopped heating, there was a mistake with the spraying. During the process of disassembling the Flow Actuator, the position of the gears was lost. Because I found out that the engine was working (it jammed, as it turned out later, and knocked everything out) and stuck it back in. I found the same working PMM and disassembled it to find out the initial position of the actuator valves. Bottom line: it is important to place the gears correctly in the splines (as described above - one groove is wider than the other 3 and a wide tooth in the wide gap of the second gear. But the further position itself, if you turn the gears before installing the engine in the actuator, is no longer important. I checked several positions, the engine scrolls and then stops to the initial state.To do this, you need to run a full test of the machine

-

Supercooling

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

This is the original position of the gears from a working SPV53 machine. Please note that the wide teeth are shifted in a circle - this is the position in the machine that corresponds to the position of the actuator flaps before starting any washing program.

-

Constantine

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

Well, we’re completely confused... the same problem, the disk and gears in the Bosch dishwasher have moved. The repairman sent the following photo, in which he disassembles the flow distributor and the gears are in a completely different position. what to do, who to believe?

-

Hater

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

Thank you, dear man, this position is correct, everything workedSuper cooling: ↑16 Feb 2022, 15:11 This is the initial position of the gears from a working SPV53 machine. Please note that the wide teeth are shifted in a circle - this is the position in the machine that corresponds to the position of the actuator flaps before starting any washing program.

PHOTO OF GEAR RESTORATION BOSCH 33A13 14 - IMG_20220214_132015.jpg

-

Digital Timer

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

Good afternoon, the actuator main gear oil seal is leaking, maybe someone knows the number spare parts and is the repair kit for sale? Thank you

-

Lena

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

Thank you kind people! We collected it from the last photo, where the double tooth of the gear faces the yellow rubber pipe, that is, the thin white disk does not block the flow of water and the terrible crackling noise disappeared after repairing the actuator. .

-

Concave Reflector System

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

People help. Assembled as in the last photo. Top washes bottom no

-

NickNickEf

- Total posts: 1

- Joined: 09.12.2023

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

Anti_Tip, Hello

Please write an email.

How did you restore the pipe

Please write an email.

How did you restore the pipe

-

Ayder

Re: PHOTO OF GEAR RESTORATION BOSCH 33A13/14

The same thing, corrected?Concave Reflector System: ↑04 Dec 2023, 04:47 People, help. Assembled as in the last photo. The top washes the bottom no

-

- Similar Topics

- Replies

- Views

- Last post

-

- 0 Replies

- 33186 Views

-

Last post by ignat.barabano

-

- 4 Replies

- 27406 Views

-

Last post by Mr.Cheese

-

- 1 Replies

- 10181 Views

-

Last post by Because of 1963

Mobile version

Mobile version